Description

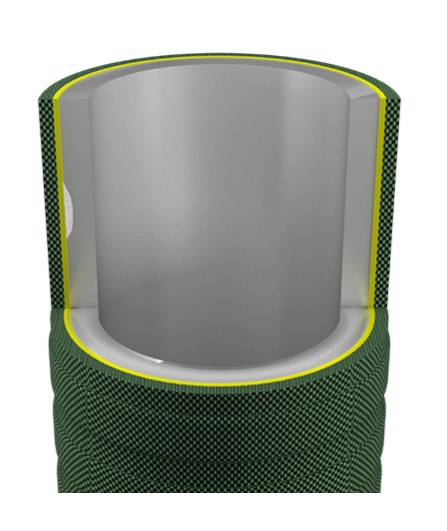

Fill-Coat #2 being pumped by air-driven mastic pump from 55 gallon drums into the casing vent. Fill-Coat #2® is designed to be installed cold out of a 55 gallon drum for small quantity requirements. It remains in a firm gel consistency at ground temperatures commonly found in normal pipeline operations.

End Use

Fill-Coat #2 is used to fill the annular space between the pipeline casing and the carrier pipe. It displaces water that may be present and it prevents water from re-entering thereby mitigating any further corrosion.

Application Procedures

Fill-Coat #2 is shipped directly to the jobsite in 55 gallon drums and pumped (at temperatures above 55°F) by air driven mastic pump directly into the casing through one casing vent until it flows from the opposite vent. Fill-Coat #2 can be heated and pumped as a liquid if desired. A 10:1 ratio mastic pump with follower plate is available from Trenton on a rental basis.

Packaging

55 gallon drums

Specifications

|

Color |

Dark Brown |

|

Specific Gravity at 60°F |

.80 – .90 |

|

Pour Point |

80 – 100°F |

|

Flash Point |

300°F |

Advantages

-

Presents galvanic and atmospheric corrosion within casings

-

Displaces and prevents re-entry of water in casing

-

Satisfies DOT requirements for shorted casings

-

Carrier pipe can be removed

-

Inert, non-hazardous, and non-volatile

-

Pumpable at temperatures above 55°F without heating

-

Economical for small quantity requirements

Quantity Requirements

|

Pipe x Casing Size |

(in inches) Gallon/Foot |

|

4 x 8 |

1.8 |

|

6 x 10 |

2.3 |

|

8 x 12 |

3.0 |

|

10 x 14 |

2.5 |

|

12 x 16 |

2.9 |

|

14 x 20 |

7.2 |

|

16 x 20 |

4.8 |

|

20 x 24 |

5.9 |

|

22 x 26 |

6.0 |

|

24 x 30 |

11.4 |

|

26 x 30 |

7.3 |

|

30 x 34 |

8.3 |

|

30 x 36 |

14.1 |

|

36 x 42 |

16.4 |