When shutdown is not an option, NRI’s Engineered Composite Repairs (ECR) systems offer a permanent, cost-effective repair to natural gas pipelines. Whether it is an active leak or external corrosion, NRI’s Trident family of products are a superior alternative, both in performance and value over traditional repair go-to options such as steel sleeves or complete pipeline replacement of the affected area. NRI’s Trident products are simple and quick to apply without service interruptions, costly additional labor and the long-drawn-out repair process associated with outdated, traditional methods.

Leak Repair

NRI’s leak repair product permanently seals active leaks, up to 60 psi (4 bar) without interruption to service. Trident Seal® repairs natural gas leaks on threaded fittings, manifold, meter sets and more.

- Live natural gas leaks on:

- Threaded fittings

- Manifold

- Meter set

- Pinhole

- Mainline

- Used above and below ground

Atmospheric Corrosion

NRI’s atmospheric corrosion repair products will repair non-leaking natural gas risers exhibiting wall loss up to 80%

- Corrosion repair on natural gas piping

- Atmospheric corrosion

- Riser reinforcement

- New or old riser assemblies

- Underground piping

- Corrosion protection

- Coating repair

- Air to soil interface

Engineered Composite Repairs (ECR)

Repair and reinforce internal corrosion and surface anomalies without the costly downtime required of traditional methods. NRI offers operator qualified (OQ) engineered system that were designed to conform to and are recognized by ASME PCC-2, ASME B31, ISO TS24817, DOT, API, and CSA Z662 standards for nonmetallic reinforcing solutions, thus ensuring product application integrity. Their extreme strength design minimizes the time and cost of refurbishment by reducing the time to repair, as well as the replacement cost. When used with the appropriate primary coating, Syntho-Glass XT enables the repair and reinforcement of virtually any geometry in minutes.

|

|

|

|

|

|

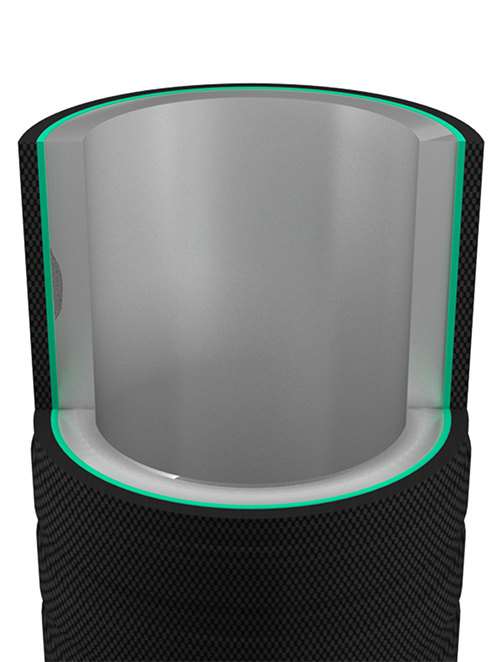

Toughest Field Applied ARO

Protect field joint coatings from the abrasion stresses and scarring of directional drilling, HDD and boring with the toughest field applied ARO, Scar-Guard®. The patented system creates an abrasion resistant, sacrificial outer laminate which protects pre-approved field joint coatings and mainline coating such as epoxies, shrink sleeves, and FBE. Scar-Guard with its controlled set times, packaging and extreme conformability provide for efficient installations in any project environment.

.jpeg)