Description

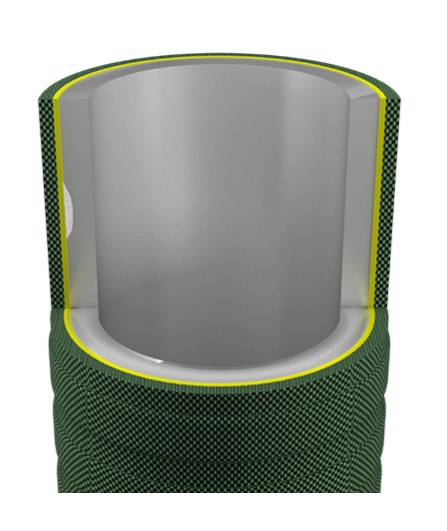

Wax-Tape® #2 wrap is a nonwoven, nonstitch bonded synthetic fabric, saturated with a blend of microcrystalline wax, solvents and corrosion inhibitors (no clay fillers), forming a tape wrapper that firms up and is suitable for painting.

End Use

For application on aboveground and belowground metal surfaces, pipe or fittings to prevent corrosion. Excellent for use when abrasive blasting or painting is impractical. Resists weathering and UV without the need for an additional outercoat or outerwrap.

Application Procedures

Wire brush and scrape the surface clean of loose mill scale, rust, paint and other foreign matter. Apply a thin film of Wax-Tape® Primer. If the surface is wet, cold or rusty, then rub and press on primer firmly to displace the moisture and ensure adhesion. Then wrap Wax-Tape #2 using a 1” overlap. While wrapping, press and mold the wrap into conformity, ensuring that there are no air pockets or voids, so that the wrap is in intimate contact with the surface. Also, press and smooth out lap seams to ensure that they are sealed. If the wrap is going to be painted, allow a few days for it to firm up.

Packaging

2″ x 9′ rolls (48 rolls/case)

4″ x 9′ rolls (24 rolls/case)

6″ x 9′ rolls (16 rolls/case)

6″ x 18′ rolls (8 rolls/case)

9″ x 18′ rolls (6 rolls/case)

12″ x 18′ rolls (4 rolls/case)

Special widths and lengths available

Specifications

Wax-Tape® #2

| Color | Brown |

| Thickness | 70-90 mils |

| Dielectric strength | 170 volts/mil |

| Operating temperature | -50-140°F |

| Saturant pour point | 125-135°F |

Wax-Tape® #2

| Color | Aluminum |

| Thickness | 70-90 mils |

| Dielectric strength | 170 volts/mil |

| Operating temperature | -50-140°F |

| Saturant pour point | 125-135°F |

| *Also available in white, yellow, red, blue and green | |

Advantages

- Minimal surface preparation

- Readily conforms to irregular shapes

- Nontoxic, noncarcinogenic, contains low VOCs

- Resistant to corrosive industrial atmospheres

- Can be applied over wet surfaces

- Compatible with other coatings

- Tape firms up and does not require additional outercoat or outerwrap

- Excellent resistance to

weathering

and UV - Can be painted after firming up